Nitinol Processing

Nitinol, a nickel-titanium (NiTi) alloy, enabling many technological advances in a growing array of therapeutic areas including structural heart, peripheral vascular, electrophysiology, neurovascular, and orthopedics. Our expertise in highspeed femtosecond laser cutting, shape setting, electropolishing, abrasive blasting and passivating enables medtech innovators to leverage this revolutionary material with comprehensive processing and manufacturing solutions.

Core Capabilities

Laser Cutting

We offer fast laser processing service with rare gas protection with high control of precision, process tube range from 0.5 to 10 mm, to a more accurate net shape right off laser.

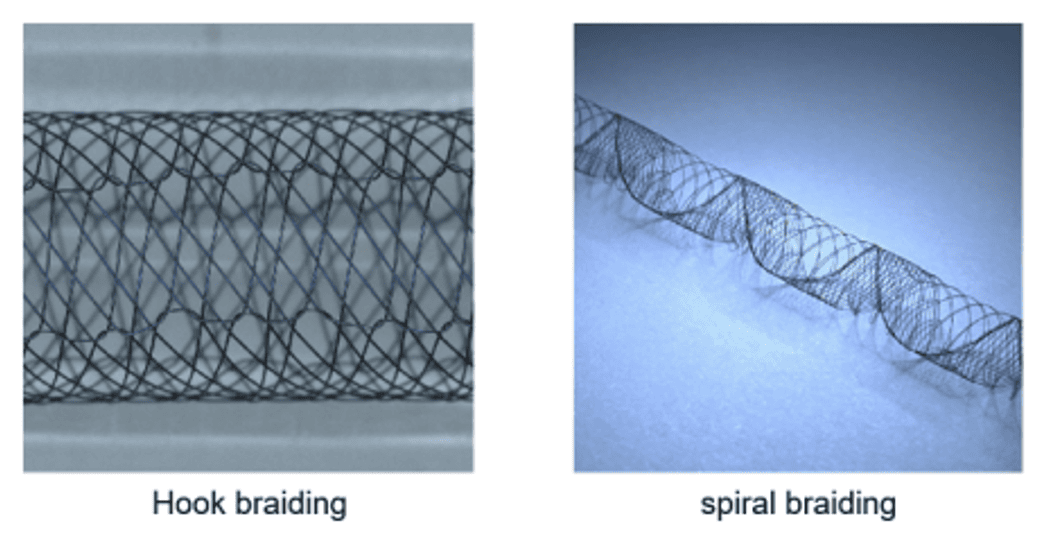

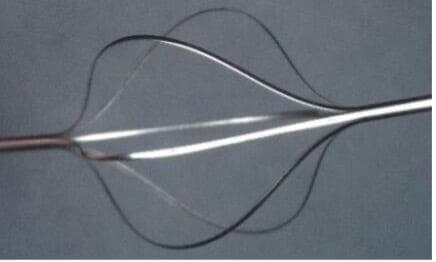

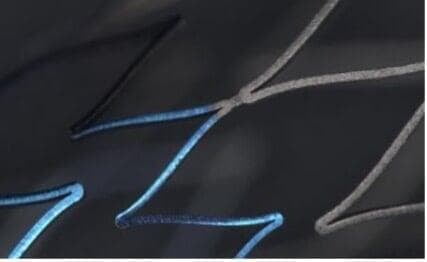

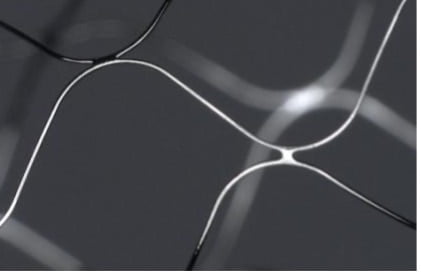

Braiding structure design

We offer carrier ends ranging from 12 to 96, each with an independent control system to ensure that the production requirements of these braiding structures are met and heated to form the preferred size. We are able to carry out further processing, such as coatings, to meet more specific needs.

We provide repeatable structures with high precision, such as Multi-Pitch Braiding, Z-axis Braiding, Hook Braiding, Tubular to Rope Braiding, Closing End Braiding and etc.

Shape Setting

We offer temperature range from RT to 900℃ for secondary shape settings based on application requirements using heat treatment furnace or salt bath furnace for advanced heating process. Moreover, the Af point of Nitinols can be adjusted to a reasonable range to utilize its shape memory property in this step to achieve specific functions.

Abrasive blasting

We offer abrasive blasting service with abrasive diameter down to 5um to remove the oxide layer of metal parts to create better conditions for post-processing such as electropolishing.

Electropolishing

We offer electropolishing service to obtain lustrous smooth surface with low roughness, process feature sizes from 0.010 to 10 mm with a max material size of 50 mm no matter the complexity of the parts.

Passivating

KAIROS Medtech offers passivating service to achieve flawless surface finishing and form a protective film, which can greatly retarding metal corrosion for specific metals.